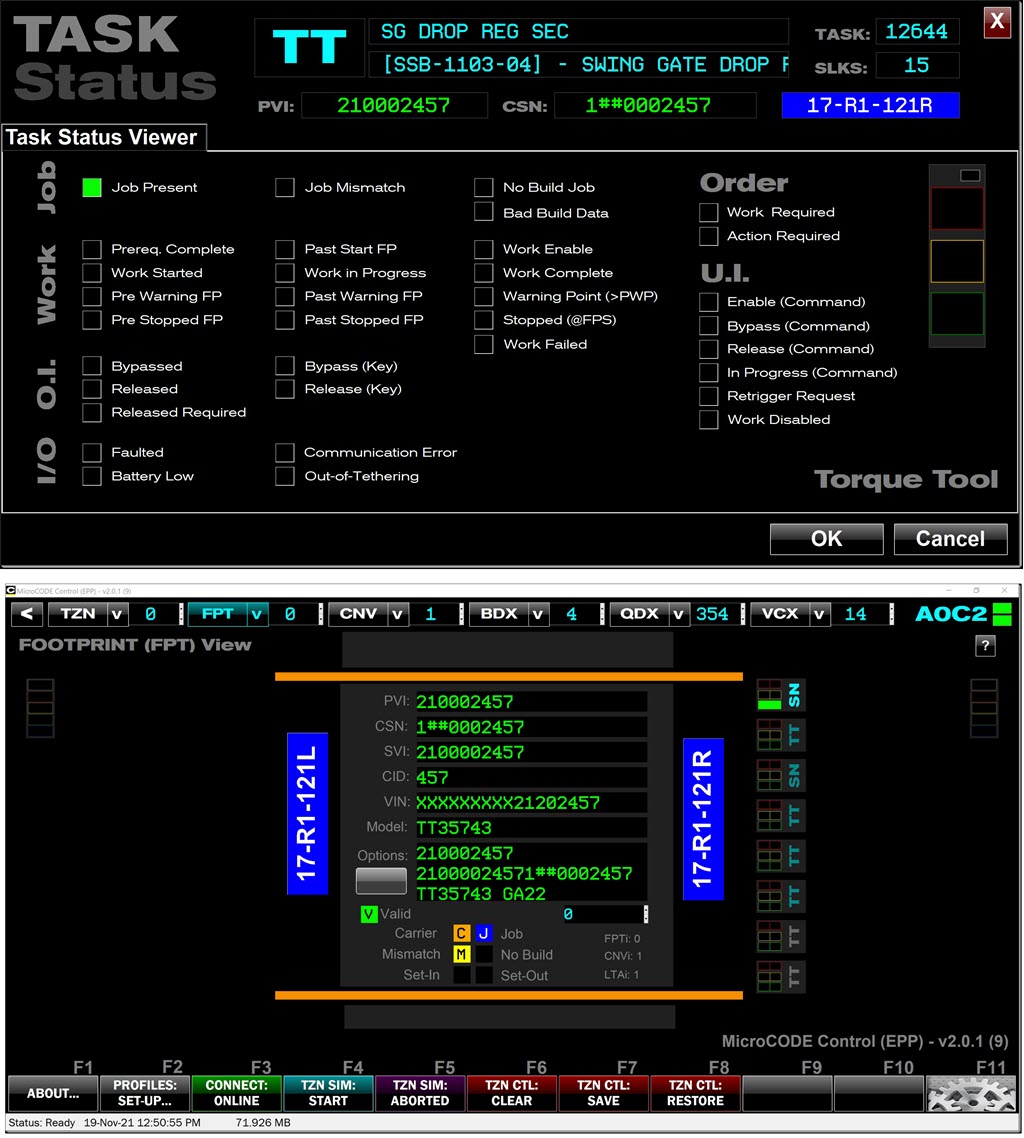

When General Motors decided to build the new all-electric Hummer in a completely refreshed Plant Zero, with a brand-new error proofing platform (EPP), one thing didn't change. GM turned to MicroCODE again and asked if we could replicate the success of the Control (SEP) App for the new EPP Manufacturing system that would be used in Plant Zero instead of SEP. And we did, in little over 6 months we produced a version of our Control App for the brand-new EPP system being used to built the next generation of all-electric trucks at General Motors!

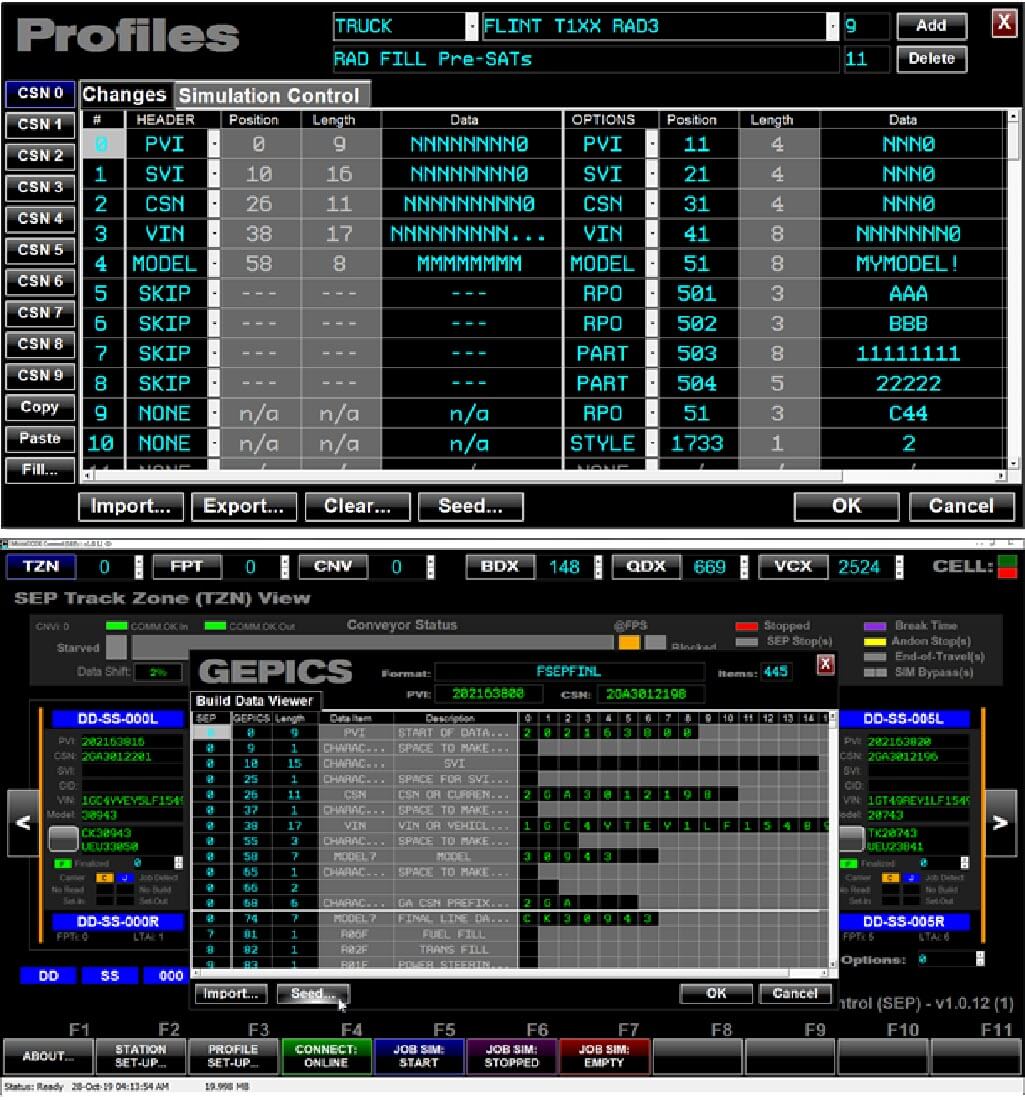

Part of the issue with testing Assembly Plant systems at a Build Shop is that the Supplier does not have a connection to a 'real' GM production environment. Plants do not want outside connections that are doing simulations and testing while they are building customer vehicles. Enter MicroCODE's Control App, where the supplier's engineers can generate their own orders on-the-fly from easily configured 'Profiles'. We often heard during training: "This can really generate Vehicle Orders without a GEPICS connection?" - Why yes it can, when you're in Control℠.

This application must run on engineer laptops, disconnected from the Internet, connected only to a local area network with the equipment being tested. This necessitated a stand-alone, self-contained Windows app that did not require a Server. You're in Control.NET™℠.